What is the cost difference between standard and premium industrial c...

In the complex web of industrial operations, industrial cables serve as the lifeline, ensuring the smooth transmission of power and signals. For enterprises, when selecting between standard and premium industrial cables, understanding the cost difference is crucial for making informed decisions that balance performance and budget.

Material Costs

The materials used in industrial cables have a significant impact on their costs. Standard industrial cables usually adopt common copper or aluminum as conductors. These materials are widely available in the market, so their raw material costs are relatively low. For example, the price of ordinary copper used in standard cables may be around $X per kilogram.

In contrast, premium industrial cables often use high-purity copper or even special alloys. High-purity copper has better conductivity, which can reduce energy loss during transmission. The production process of high-purity copper is more complex, resulting in a higher price, possibly around $Y per kilogram, where Y is significantly larger than X. In addition, the insulation materials of premium cables are also of higher quality, such as special fluoropolymers, which have better high-temperature resistance and corrosion resistance, further increasing the material cost.

**

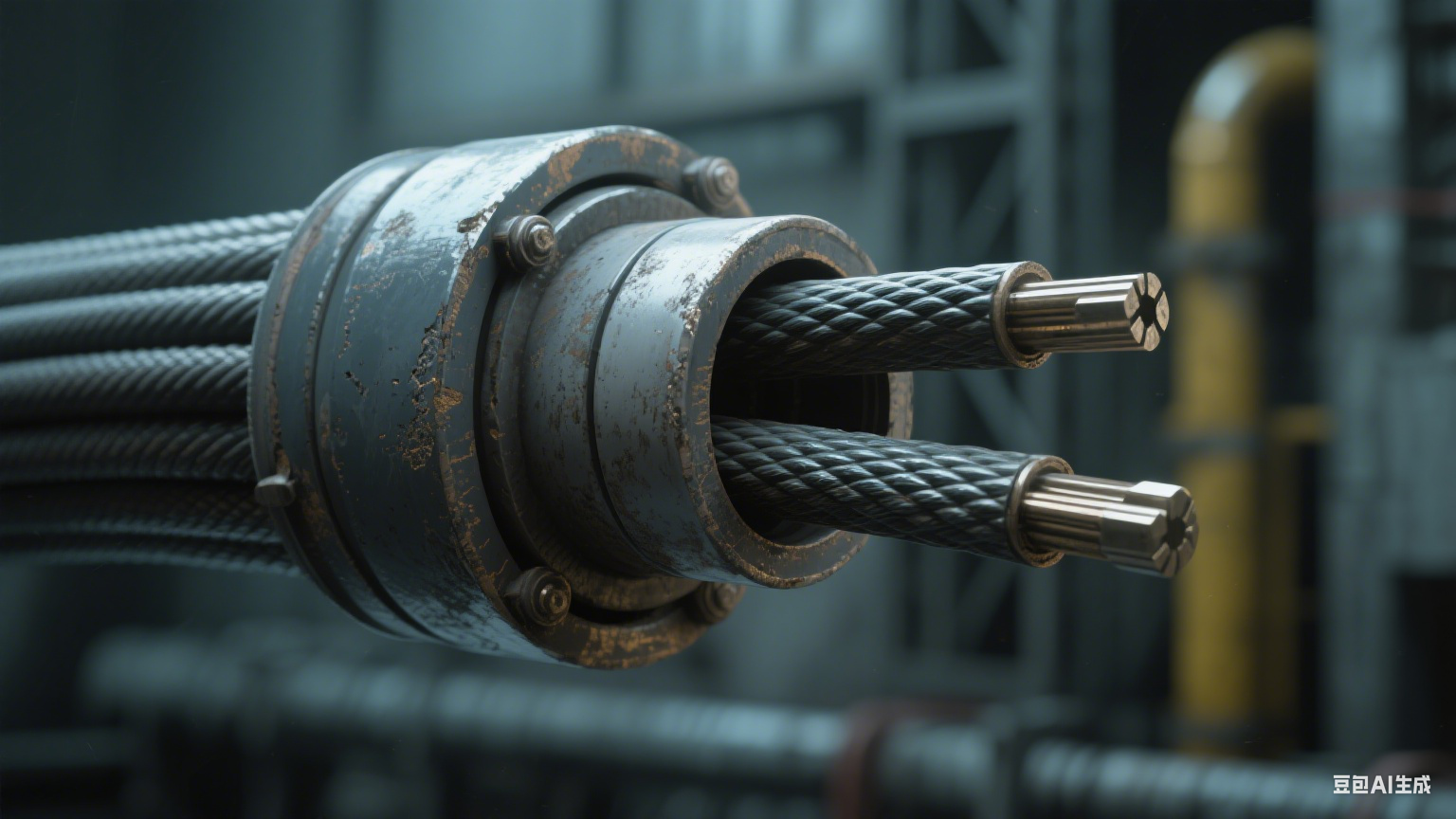

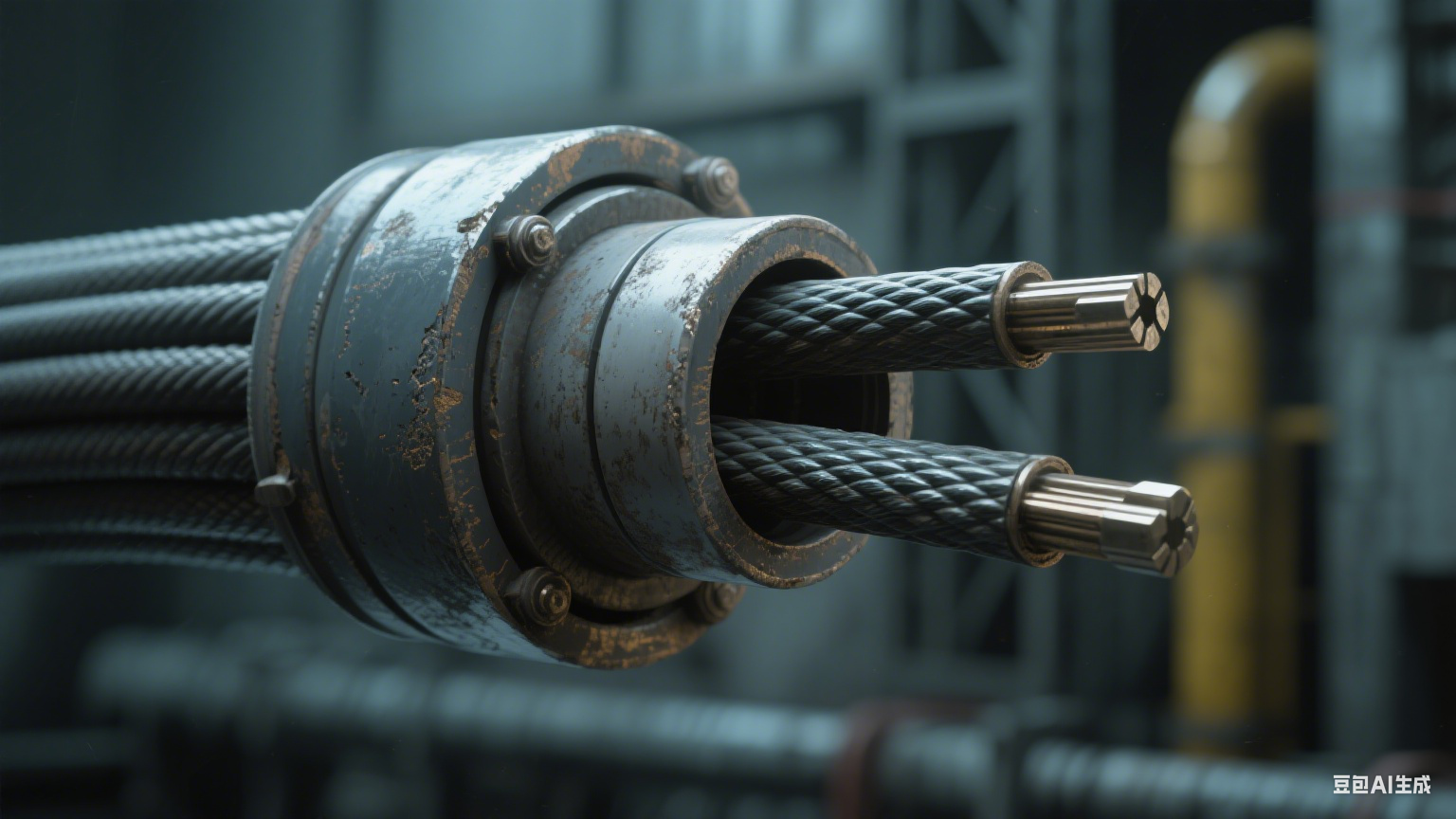

(500*500px) – This is a picture of a standard industrial cable with common materials.

**

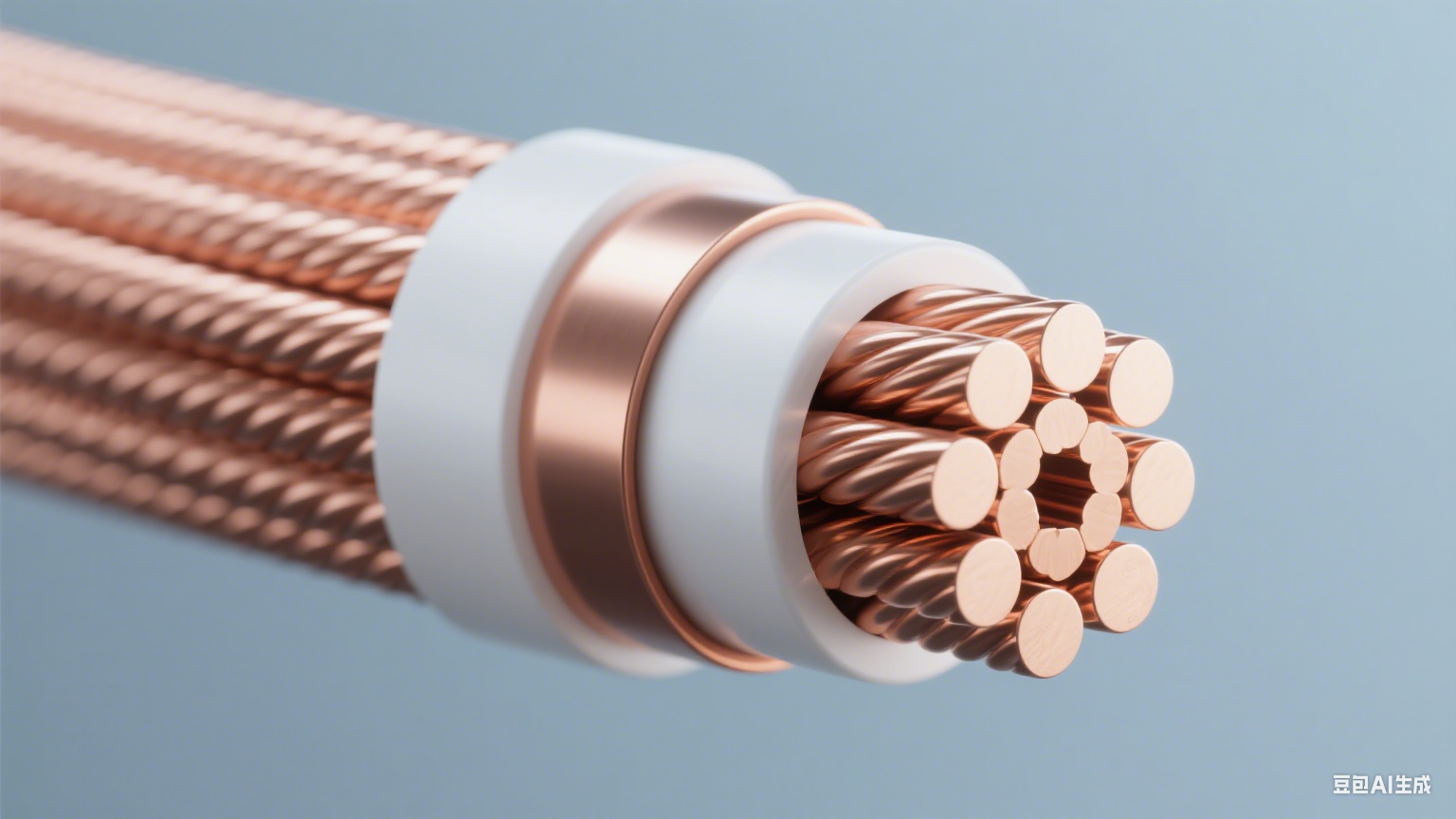

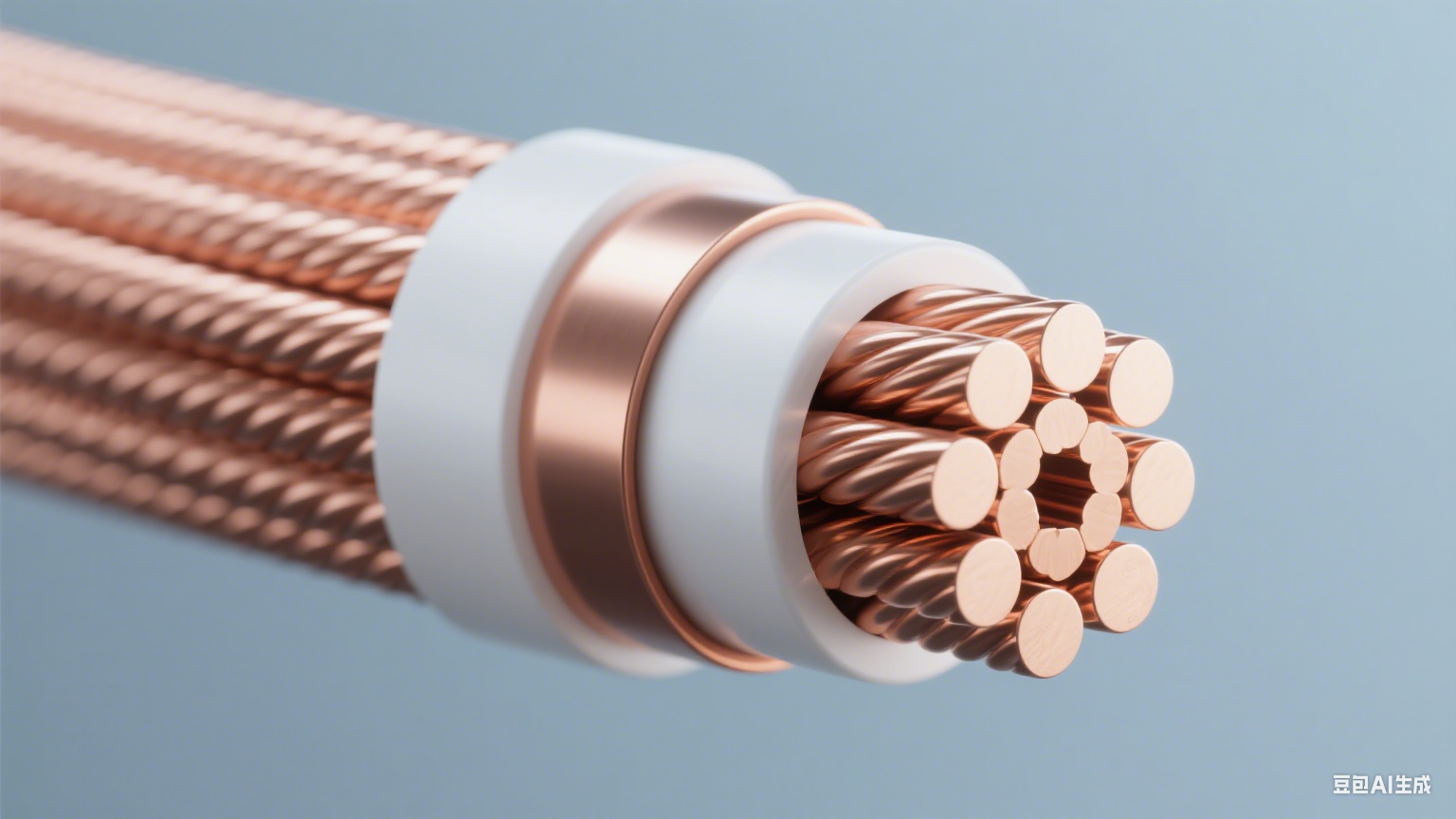

(500*500px) – This shows a premium industrial cable made of high-purity copper and high-quality insulation materials.

Production Process Costs

The production process of standard industrial cables is relatively simple. The manufacturing steps mainly include conductor drawing, insulation extrusion, and cable stranding, which can be completed with ordinary production equipment. The requirements for production precision are not extremely high, and the production efficiency is relatively high, thus the labor and equipment costs involved are lower.

Premium industrial cables, on the other hand, require more sophisticated production processes. For instance, in the conductor manufacturing stage, strict control is needed to ensure the purity of the material. The insulation layer processing requires more precise extrusion technology to ensure uniform thickness and excellent performance. Moreover, premium cables often undergo more rigorous testing procedures, such as high-temperature resistance tests, pressure tests, and signal transmission stability tests, which add to the production cost. The advanced equipment and skilled technicians required for these processes also make the production cost of premium cables much higher than that of standard ones.

Performance-Related Costs

From a long-term perspective, performance differences also lead to cost differences. Standard cables have general performance in terms of temperature resistance, corrosion resistance, and service life. In harsh industrial environments, they may need to be replaced frequently, which increases the maintenance and replacement costs. For example, in a high-temperature workshop, a standard cable may need to be replaced every 2-3 years.

Premium cables, with their superior performance, have a longer service life. They can withstand harsher environmental conditions, reducing the frequency of replacement. Although the initial purchase cost is high, the long-term maintenance and replacement costs are much lower. In the same high-temperature workshop, a premium cable may have a service life of 5-8 years.

Application Scenarios and Cost Adaptability

Standard industrial cables are suitable for general industrial environments with stable conditions and low requirements for cable performance, such as ordinary factory workshops with normal temperature and humidity. Their lower cost can meet the basic transmission needs here.

Premium industrial cables are more suitable for harsh environments, such as chemical plants with strong corrosion, steel mills with high temperatures, and power systems with high transmission requirements. In these scenarios, the reliable performance of premium cables can avoid production interruptions caused by cable failures, which is crucial for enterprises, and the higher cost is worthwhile.

When it comes to choosing industrial cables, FRS brand factory is your reliable partner. We have rich experience in producing both standard and premium industrial cables. Our standard cables are made of high-quality common materials through strict production processes, ensuring stable performance at an economical price. For premium cables, we use top-grade materials and advanced production technologies to meet the most demanding industrial needs. Whether you need standard cables for general applications or premium cables for harsh environments, FRS can provide you with cost-effective solutions. Choose FRS, and ensure the smooth operation of your industrial systems.