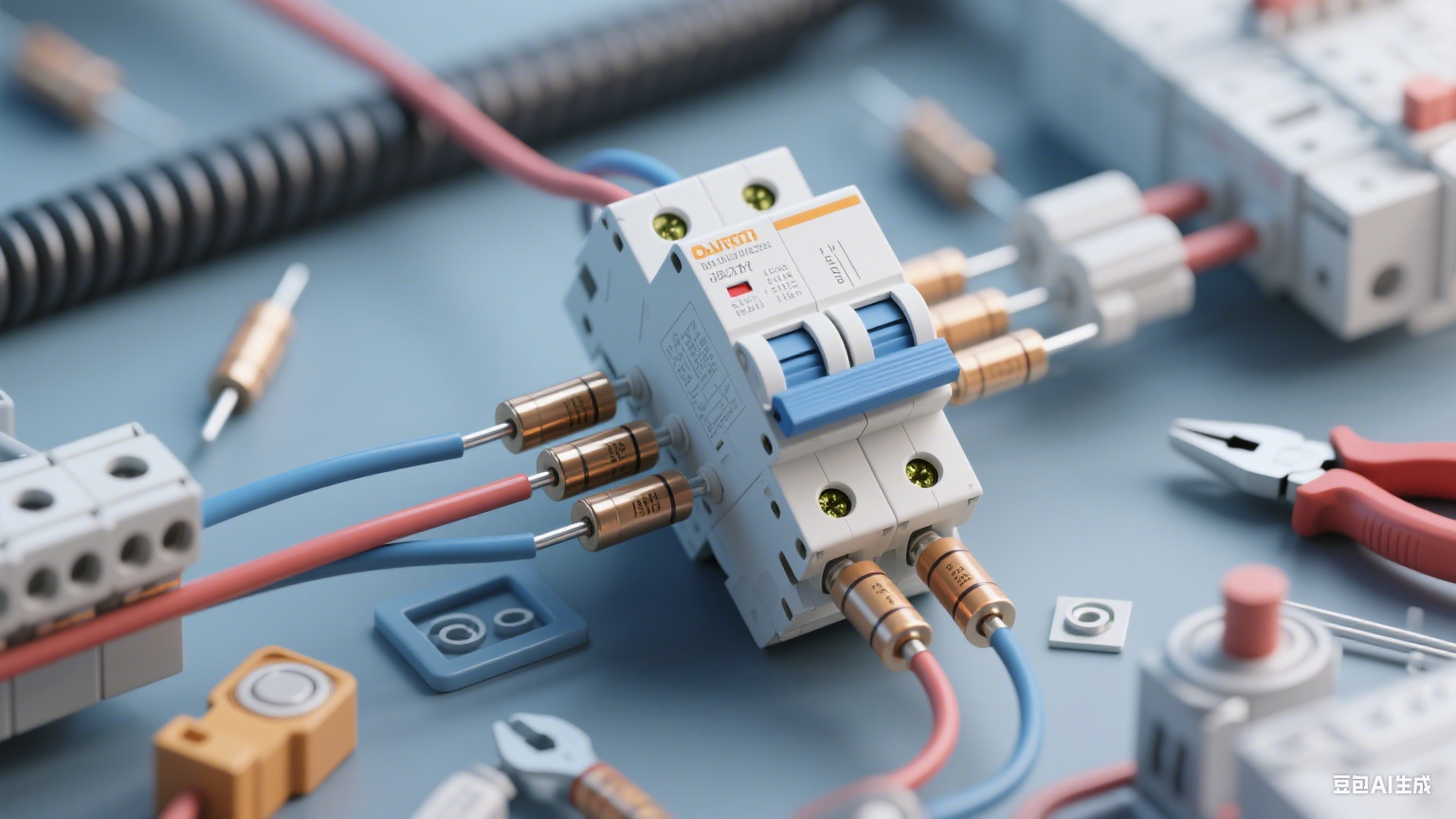

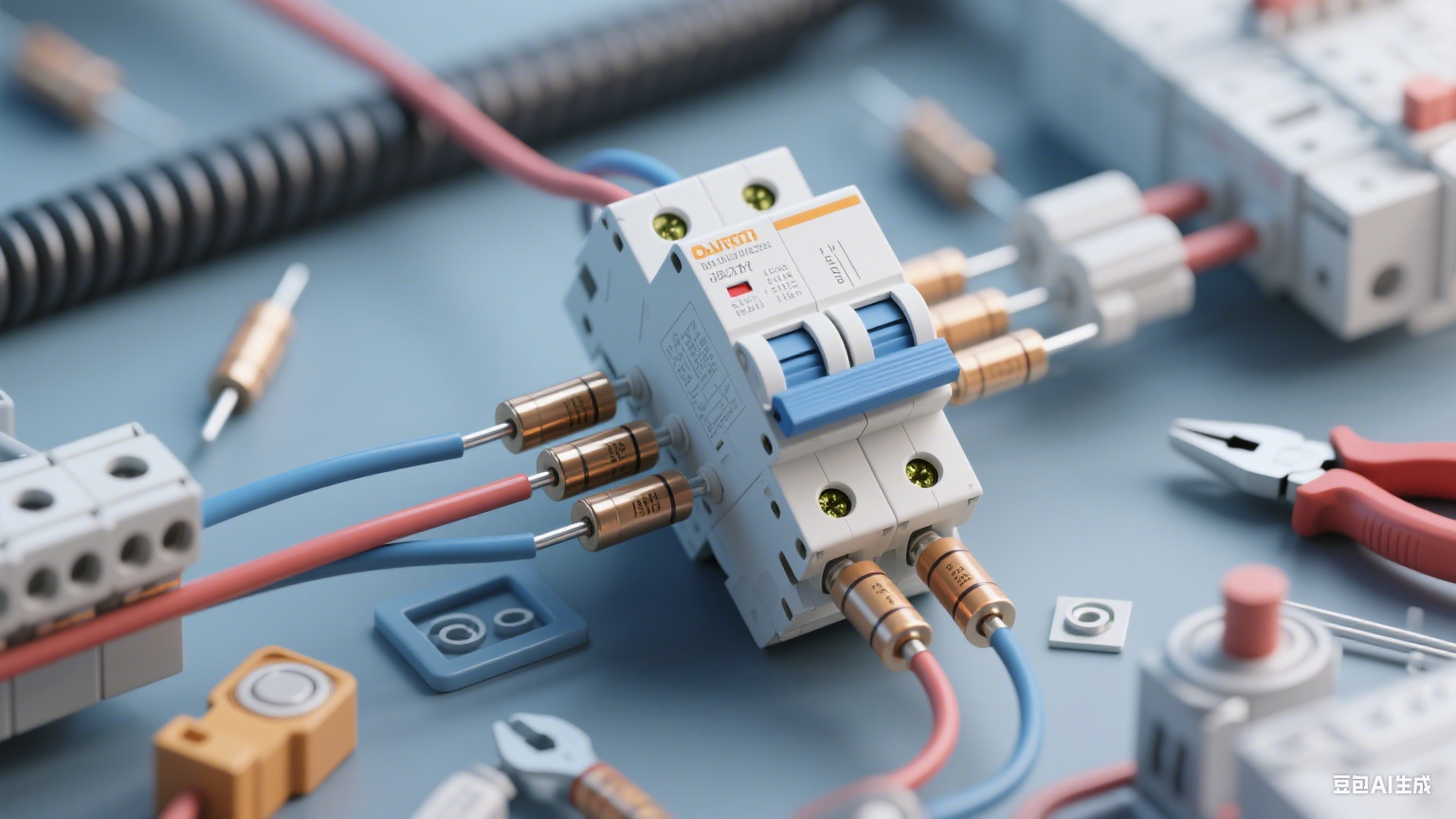

How to prevent overheating in industrial cable systems

Overheating in industrial cable systems is a serious issue that can lead to equipment failure, production downtime, and even fire hazards. Taking effective measures to prevent overheating is crucial for ensuring the safe and efficient operation of industrial facilities.

Common causes of overheating

Overheating in industrial cable systems can result from various factors. One major cause is excessive current load. When cables carry more current than their rated capacity, the resistance in the conductors generates excessive heat. This often happens when equipment is added to a circuit without upgrading the cables.

Poor ventilation is another contributing factor. Cables installed in enclosed spaces, tight conduits, or areas with high ambient temperatures struggle to dissipate heat, leading to a gradual increase in temperature.

Aging and degradation of cables also play a role. Over time, the insulation material of cables can deteriorate due to exposure to heat, chemicals, or mechanical stress. This degradation reduces the cable’s ability to withstand heat and can cause overheating.

Incorrect installation is yet another cause. Cables that are bent too sharply, crushed, or not properly secured can experience increased resistance, which in turn generates heat.

Effective prevention measures

Proper design and selection

Choosing the right cables for the application is the first step in preventing overheating. Cables should be selected based on the maximum current they will carry, as well as the environmental conditions such as temperature, humidity, and exposure to chemicals. It is important to consult the cable manufacturer’s specifications and ensure that the cables have a sufficient current-carrying capacity.

In addition, the design of the cable system should allow for proper heat dissipation. This may involve using larger conductors, providing adequate spacing between cables, and avoiding routing cables through areas with high temperatures.

Installation practices

Proper installation is essential to prevent overheating. Cables should be installed according to the manufacturer’s guidelines and industry standards. This includes avoiding sharp bends, ensuring proper support, and not overcrowding conduits or cable trays.

Ventilation should be considered during installation. In enclosed spaces, installing fans or other cooling systems can help circulate air and remove heat. Cables should also be kept away from heat sources such as boilers, furnaces, and motors.

Regular maintenance and inspection

Implementing a regular maintenance and inspection program is key to detecting and preventing overheating. Inspections should include checking for signs of damage to cables, such as cracks in insulation, corrosion, or overheating marks.

Thermal imaging can be a useful tool for identifying hot spots in cable systems. By using a thermal camera, technicians can detect areas where cables are overheating before they cause serious problems.

Cleaning cables and cable trays regularly can also help improve heat dissipation. Dust and debris can accumulate on cables, acting as an insulator and trapping heat.

Monitoring and control

Installing monitoring systems can provide real-time data on the temperature of cables. This allows for early detection of overheating and enables prompt action to be taken. Some monitoring systems can even send alerts when temperatures exceed a certain threshold.

Circuit breakers and fuses are important safety devices that can prevent excessive current from flowing through cables. They should be properly sized and regularly tested to ensure they are functioning correctly.

**

(500*500px)

When it comes to ensuring the reliability and safety of industrial cable systems, FRS brand factory is your trusted partner. FRS is committed to producing high-quality cables that are designed to withstand the rigors of industrial environments. Our cables are manufactured with superior insulation materials and undergo strict testing to ensure they meet or exceed industry standards. With FRS cables, you can minimize the risk of overheating and keep your industrial operations running smoothly. Choose FRS for reliable and durable industrial cable solutions.